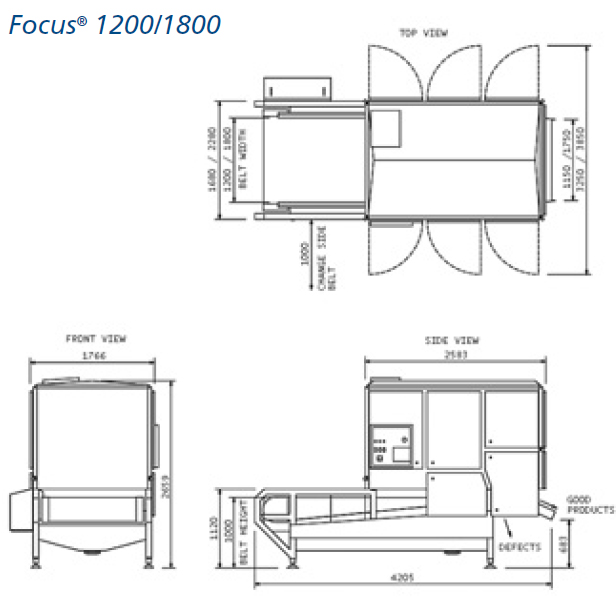

FOCUS

The optical sorting machine

Main features:

- The only belt sorter in the world with a usable belt width of 2400 mm.

- Available belt width: 2400, 1800, 1200 and 600 mm.

- User friendly color LCD with touch screen.

- Can be used for wet, dry and frozen products.

- Automatic adjustable ejection unit and separation plate.

- Water and dust proof stainless steel housing.

- Modular construction.

- Product belt easy and quick exchangeable.

- Latest computer, camera and lighting techniques.

- Color cameras, black/white cameras and (color-) lasers possible.

- Advanced shape recognition software.

- Low and predictable maintenance costs.

The Concept Engineers Focus is a machine specially designed to optically sort products with various visual defects. Blemishes and other undesirable elements in a product stream of potato, vegetable, fruit and/or seafood products are detected and removed.

The possibility of increasing the quality of the end product and replacing the labour-intensive inspection belts are one of the many advantages of the Focus.

Furthermore, the Focus is a multipurpose machine.

Technical Information

The Focus consists of a frame in which a fastrunning belt is mounted. The processed product is evenly divided and alligned on the belt by means of a Concept Engineers infeed vibrator.

One or more lighting systems provide a good and even illumination of the product. Defect and foreign elements on the product are scanned and identified by means of line scan cameras. The computer, to which the cameras are connected, actuates the relevant ejection unit(s) to ensure that each identified defect is separated from the product flow. In principle unlimited addition of cameras is possible.

The Focus can easily be installed in various positions in the production line. Concept Engineers has the in-house ability to carry out the complete engineering of the optical sorting area. This means: supply of the machinery may include infeed vibrator, defect-return and double-check systems, routing and installation into a new or existing production line. The Focus has a modular construction, meaning that the frame of the machine can easily be adjusted to suit the processing of many kinds of products. Inside the housing various detection spots have been designed for color or black/white cameras (on/off belt scanning) and can be mounted in various detection positions (angles).

Sorting by means of UV- or IR-light and also laser detection is possible. The Focus is constructed according to the current CE regulations and is fully built out of stainless steel.

NEXUS

The Optical Free Fall Sorter

Main features:

- Latest computer, camera- & lighting techniques

- Trusted simple touch screen HMI

- Stainless steel housing IP 63

- Low, predictable maintenance costs

- Quickly, easily changeable conveyor belt

- Color and/or monochromatic cameras

- Modular construction

- Operational width of 1000 or 1200mm

- High sorting results

- Insensitive to conveyor belt discoloration

- No water usage due to closed cooling system

The Concept Engineers Nexus is specifically developed to sort small, dry product. Using the principle of free fall enables the machine to view all sides of the product.

Shape deviations and foreign objects can thus be detected and ejected from the product flow during free fall with high reliability.

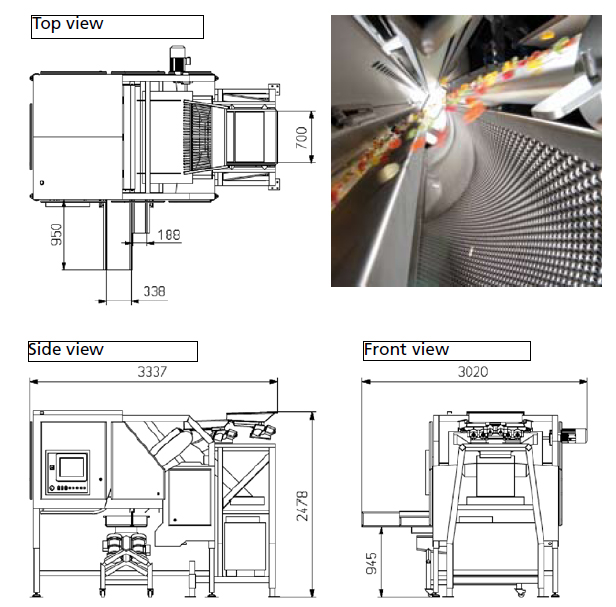

Technical Information

The Nexus consists of a frame in which a high speed conveyor belt is mounted.

Product to be processed is properly divided by an infeed vibrator and led to the belt. The product is lit by one or more types of lighting during its consecutive free fall.

Color and/or monochromatic line scan cameras detect and identify defective and foreign objects in and between products. The computer, to which the cameras are connected, controls one or more air valves that remove the defective or foreign object from the product flow.

The Nexus can be easily integrated in many locations in a production line thanks to its modular construction. Concept Engineers can execute the complete engineering for the optical sorting, which includes the delivery of the Nexus with infeed and outfeed vibrators as well as the placement of the machine in a new or existing production line.